When it comes to modern heating systems, the hot surface igniter plays a pivotal role in ensuring efficient and safe operation. Unlike traditional spark igniters, a hot surface igniter uses advanced technology to ignite fuel sources in furnaces, boilers, and HVAC units. In this article, we’ll explore how a hot surface igniter works, its benefits, and why it’s a must-have component for homeowners and technicians alike.

What Is a Hot Surface Igniter?

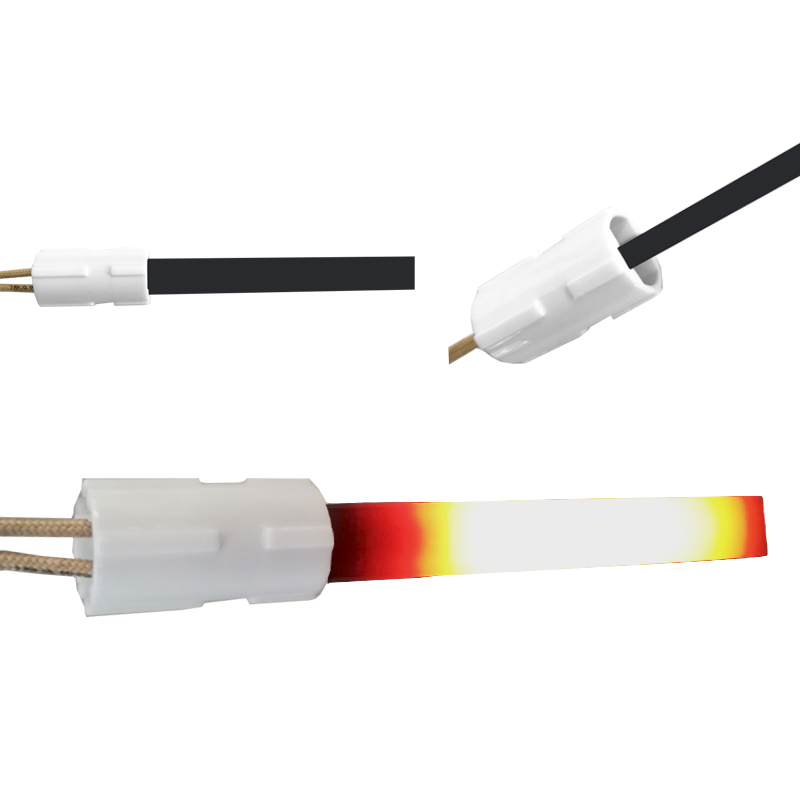

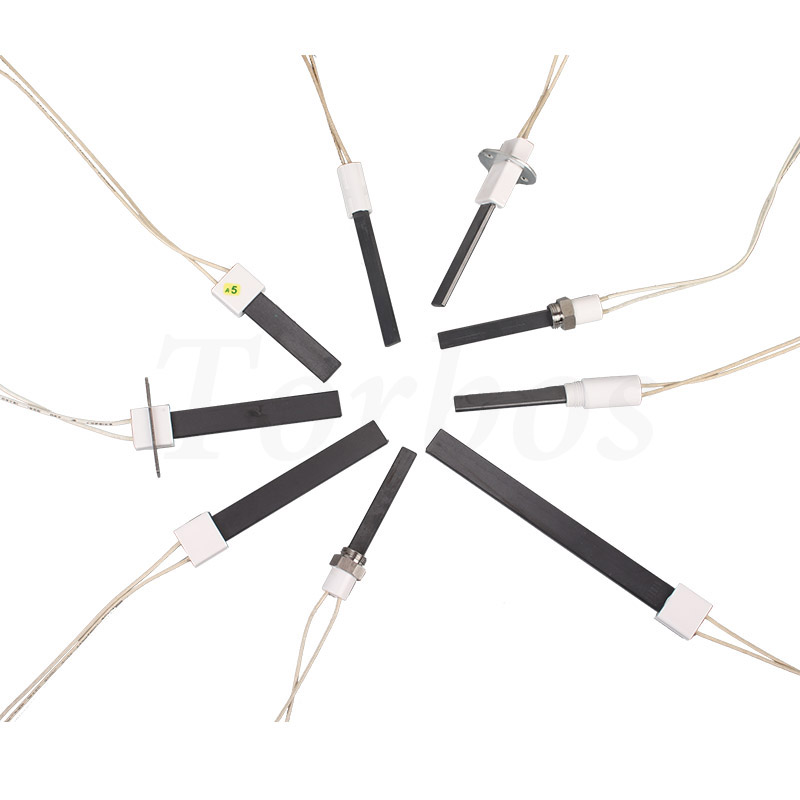

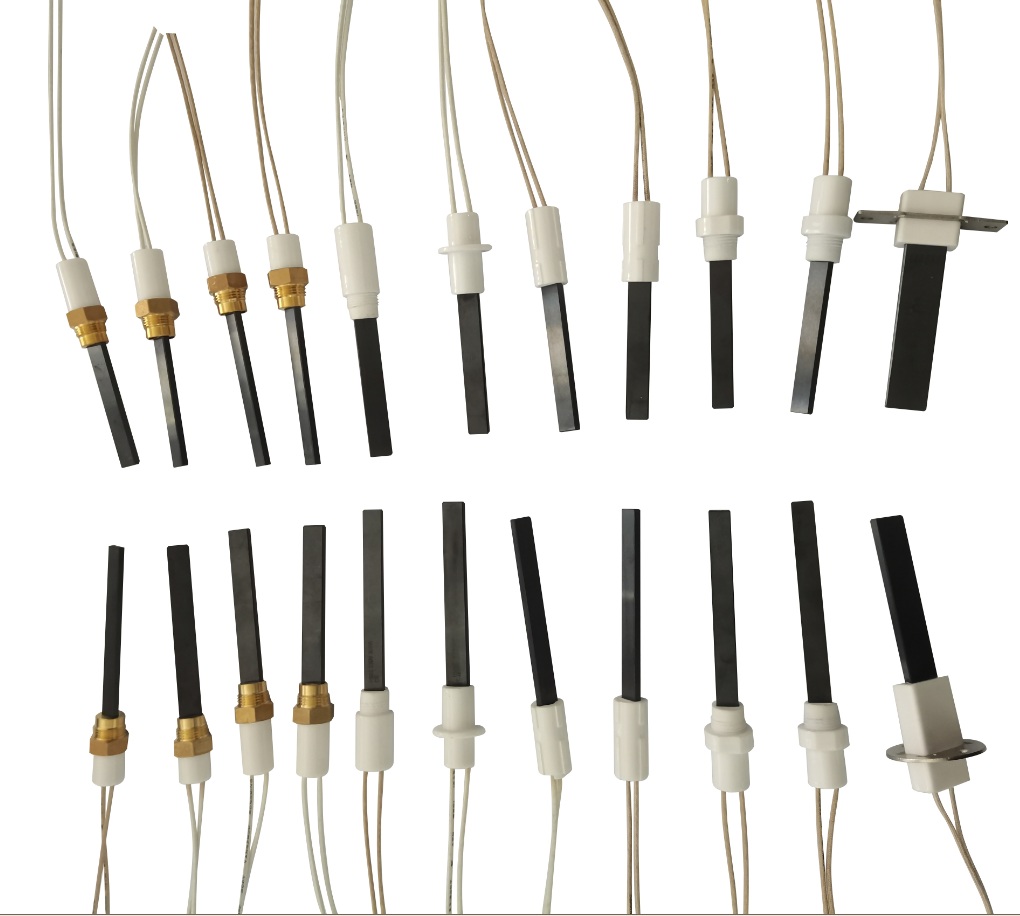

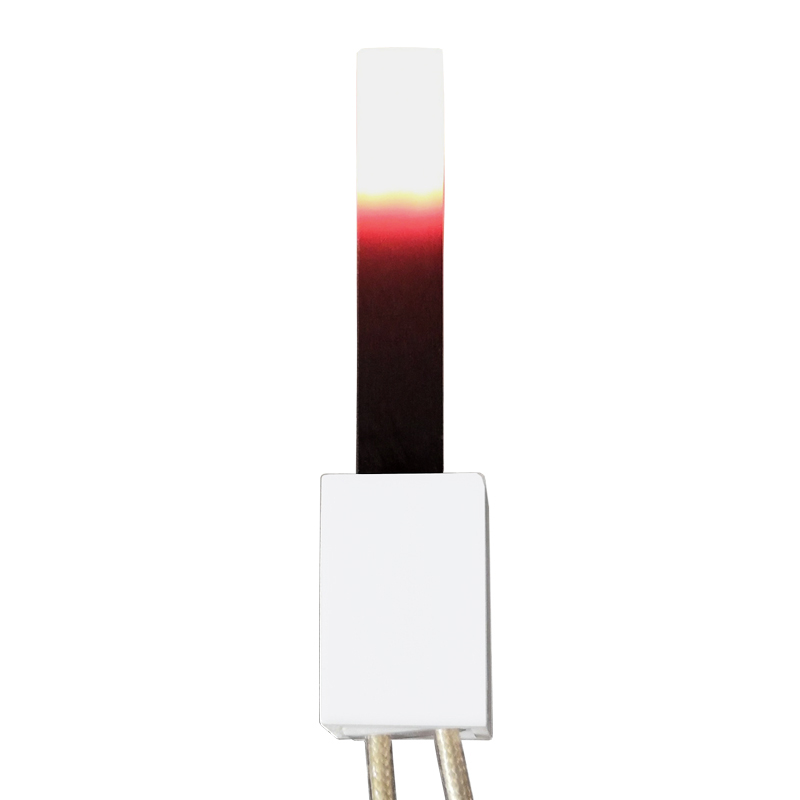

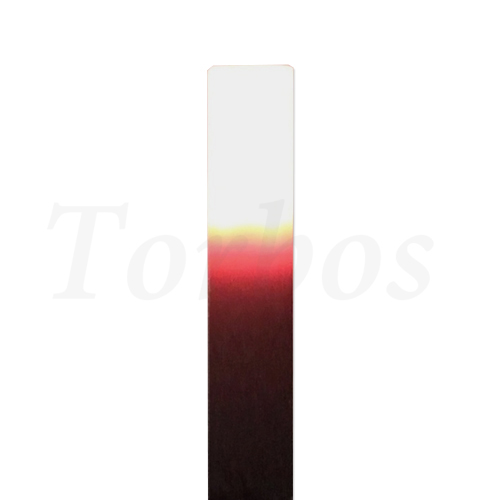

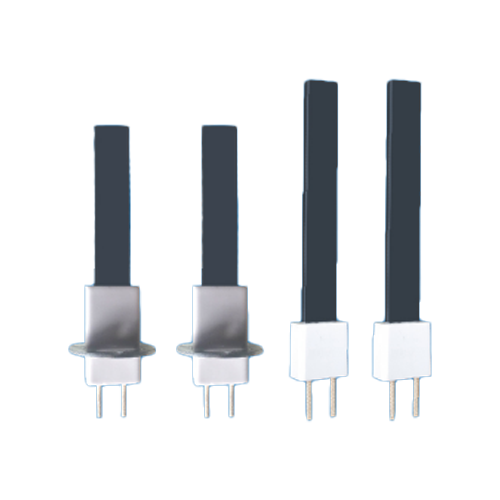

A hot surface igniter is an electrically heated device made from durable materials like silicon carbide or nitride. When energized, it glows white-hot (often exceeding 2,500°F) to ignite gas or oil in heating systems. This method eliminates the need for a pilot light, making it more energy-efficient and reliable.

How Does a Hot Surface Igniter Work?

Activation: When the thermostat signals the need for heat, electricity flows to the hot surface igniter.

Heating: The igniter rapidly heats up, reaching temperatures high enough to ignite fuel.

Ignition: Gas or oil is released, and the hot surface igniter triggers combustion, starting the heating cycle.

This seamless process reduces wear and tear compared to spark-based systems, ensuring longer-lasting performance.

Key Benefits of a Hot Surface Igniter

Energy Efficiency: By eliminating a constantly burning pilot light, a hot surface igniter cuts energy waste and lowers utility bills.

Durability: Made from robust materials, it withstands extreme temperatures and frequent use.

Safety: Fewer moving parts mean reduced risk of malfunctions or gas leaks.

Quiet Operation: Unlike noisy spark igniters, a hot surface igniter works silently.

Common Applications of Hot Surface Igniters

These devices are widely used in:

Residential gas furnaces

Commercial boilers

Industrial ovens

HVAC systems

Maintenance Tips for Your Hot Surface Igniter

To maximize the lifespan of your hot surface igniter:

Clean Regularly: Dust or debris can insulate the igniter, reducing efficiency.

Inspect for Cracks: Damage can lead to failure—replace cracked igniters immediately.

Schedule Professional Checkups: Technicians can test voltage and alignment during annual HVAC maintenance.

Why Choose a Hot Surface Igniter Over Alternatives?

While older systems rely on pilot lights or spark igniters, a hot surface igniter offers unmatched reliability. Its faster ignition time improves heating efficiency, and its solid-state design minimizes mechanical failures. For homeowners seeking consistent warmth and lower operating costs, upgrading to a hot surface igniter is a smart investment.

Conclusion

The hot surface igniter is a cornerstone of modern heating technology, delivering efficiency, safety, and durability. Whether you’re replacing an outdated system or maintaining an existing one, understanding the role of this component ensures optimal performance. Always consult a certified technician for installation or repairs to keep your hot surface igniter—and your entire heating system—running smoothly for years to come.

By prioritizing a hot surface igniter, you’re not just investing in better ignition; you’re ensuring comfort and peace of mind during every heating season.