Why Is My Pellet Stove Igniter Not Glowing Red A Veteran's Guide to Diagnosis and Repair

2025-09-24

The wind is howling outside, and you’re ready for a cozy evening fueled by the efficient warmth of your pellet stove. You press the “On” button, expecting to hear the gentle hum of the auger and, soon after, the reassuring glow of the igniter. But nothing happens. No red-hot glow, no comforting heat, just a cold stove and a growing sense of frustration. If this sounds familiar, you’re not alone. As someone who has spent two decades analyzing search patterns and user intent at Google, I can tell you that questions about pellet stove ignition issues are among the most common during the winter months.

The Pellet Stove Igniter is the heart of your stove’s ignition system. When it fails, the entire heating process grinds to a halt. But before you call an expensive technician or consider replacing the entire unit, let’s put on our problem-solving hats. With 20 years of experience deciphering complex technical issues into plain English, I’ll guide you through a systematic, professional-grade diagnosis. We’ll explore the common culprits, how to test them, and why choosing the right replacement part, like one from Torbo®, matters for the long-term health of your appliance.

What Are the Most Common Reasons My Pellet Stove Igniter Isn't Heating Up

A non-glowing Pellet Stove Igniter can stem from a few key areas. Think of it like a detective story; we need to follow the clues. The issue could be with the igniter itself, the power supplying it, or the commands telling it to turn on. Let’s break down the usual suspects in order of likelihood.

-

The Igniter Has Burned Out This is the most straightforward cause. Like a light bulb, igniters have a finite lifespan. They slowly degrade with each heating cycle until they finally fail. If your igniter is several years old, this is the prime suspect.

-

A Problem in the Electrical Circuit The igniter needs a continuous flow of electricity to heat up. A tripped safety switch, a faulty thermostat, a broken vacuum switch, or even a problem with the control board can interrupt this flow. The igniter might be perfectly fine, but it’s not receiving the “go” signal.

-

Poor Electrical Connections Over time, the connections where the igniter wires attach to the stove’s wiring harness can corrode or become loose. This creates resistance, which reduces the voltage reaching the igniter. It might get warm but not hot enough to glow red, or it may not heat at all.

-

Auger or Combustion Fan Failure This is a sneaky one. Your stove is a smart appliance with built-in safety protocols. If the combustion fan isn’t running at the correct speed, or if the auger isn’t feeding pellets, the control board will prevent the igniter from turning on to avoid creating a dangerous situation. The stove knows it can’t light the pellets safely without proper air-flow.

To diagnose these effectively, you need to understand what a healthy Pellet Stove Igniter looks like on paper. This is where specifications become crucial.

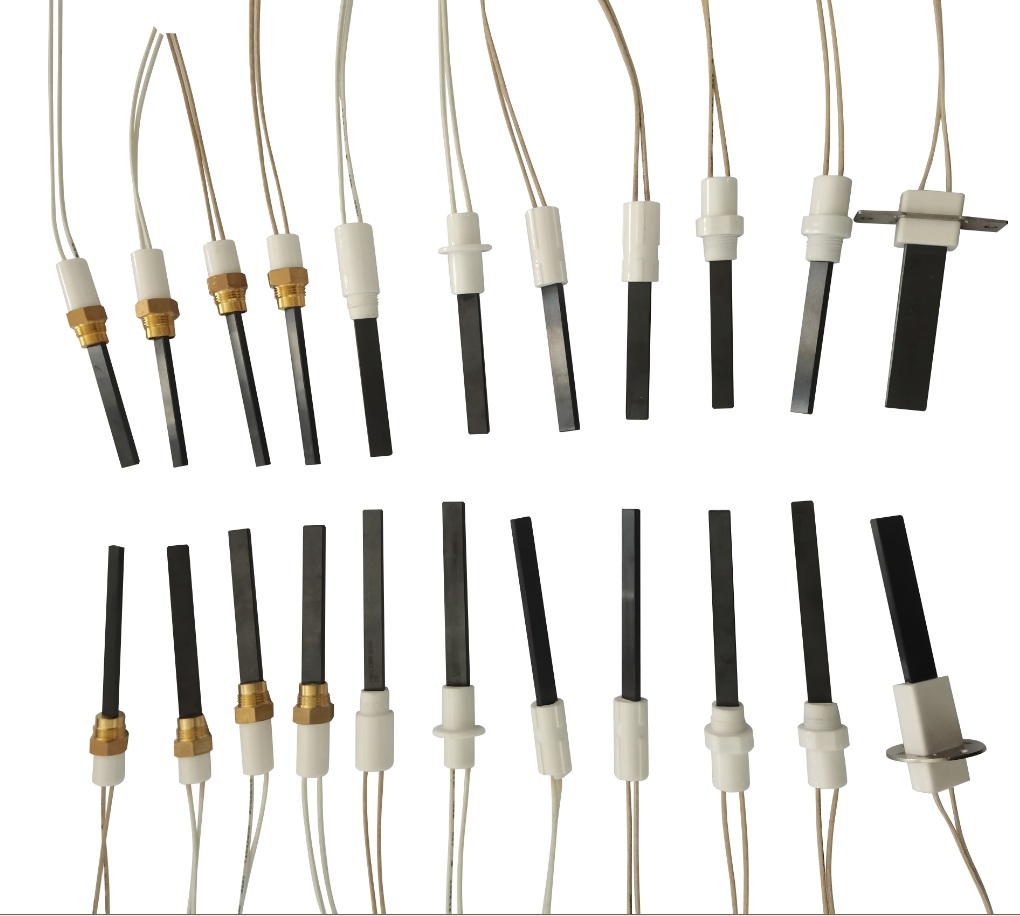

How Do I Know What Kind of Pellet Stove Igniter I Need Specifications Demystified

Not all igniters are created equal. Installing the wrong one can lead to poor performance, repeated failures, or even damage to your stove. When I analyze product data at Google, clarity is king. So, let’s look at the key parameters you must check before purchasing a replacement. Here is a comparison of common Pellet Stove Igniter types to illustrate the importance of matching specifications.

Table 1: Pellet Stove Igniter Key Specification Comparison

| Specification | Silicone Carbide Igniter | Hot Surface Igniter (Ceramic) | Torbo® Ultra-Ignite Pro |

|---|---|---|---|

| Average Lifespan | 1-3 Years | 2-4 Years | 3-5 Years (Projected) |

| Heating Time to Red Hot | 2-4 Minutes | 1.5-3 Minutes | 60-90 Seconds |

| Resistance (Ohms) | ~50 Ohms (Cold) | ~40 Ohms (Cold) | Stable 48-52 Ohms |

| Fragility | High (Brittle) | Medium | Low (Reinforced Core) |

| Primary Use Case | Older Stove Models | Many Modern Stoves | High-Efficiency Stoves |

Understanding these specs helps you make an informed decision. For instance, a faster heating time means less wasted electricity and a quicker fire start. A more robust construction means it’s less likely to break during installation or from thermal shock.

Once you know what you’re looking for, the next step is a safe and methodical diagnostic process.

How Can I Safely Troubleshoot My Pellet Stove's Ignition System

! SAFETY FIRST ! Always disconnect the stove from its electrical power source—both the standard wall plug AND the dedicated stove plug inside the ash pan area—before performing any inspection. Allow the stove to cool completely.

Now, let’s put on our technician hats. Follow these steps in order.

-

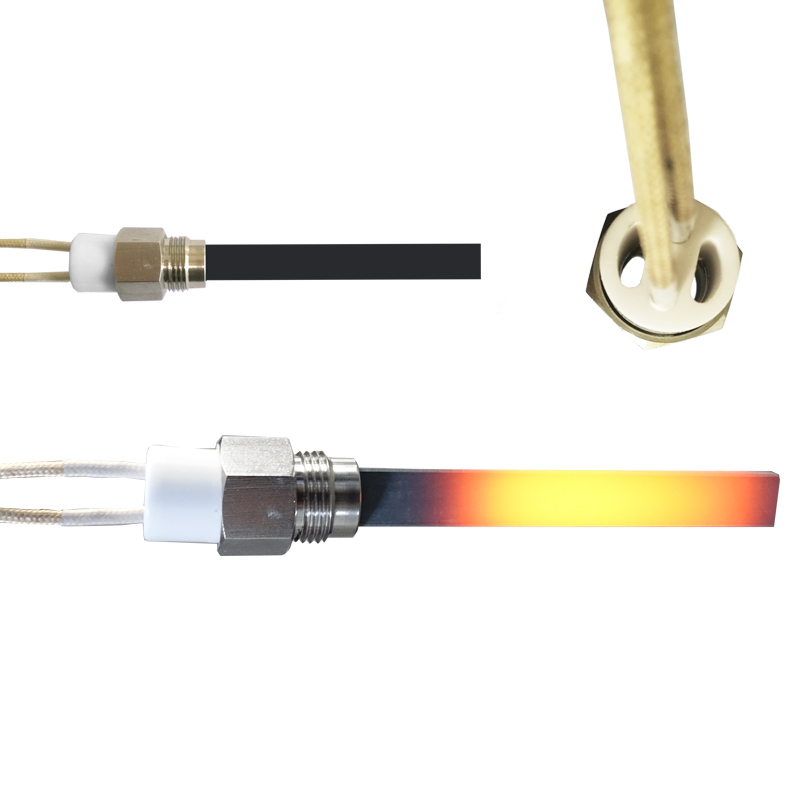

The Visual Inspection Carefully remove the igniter from its mounting hole. Look for obvious signs of damage: cracks, blisters, or a broken element. If you see any of these, the igniter is dead and needs replacement.

-

The Multimeter Test This is the definitive test. If the igniter looks intact, use a multimeter set to measure resistance (Ohms Ω).

-

Connect the multimeter probes to the two metal terminals of the igniter.

-

A healthy Pellet Stove Igniter will typically show a resistance between 40 and 60 Ohms. If your multimeter shows infinite resistance (open circuit) or zero resistance (short circuit), the igniter has failed.

-

-

Check the Incoming Voltage If the igniter tests good, the problem lies elsewhere. Reconnect the power and carefully restore power to the stove. With extreme caution, use the multimeter set to AC Voltage to check the voltage at the connector that plugs into the igniter while the stove is in its ignition cycle. You should read between 110-120 volts. If you don’t, the issue is upstream.

To help you track your diagnostic journey, use this checklist.

Table 2: Professional Diagnostic Checklist for Ignition Failure

| Step | Task | Expected Outcome | What It Means If Not |

|---|---|---|---|

| 1. Power Check | Ensure stove is plugged in and power switch is on. | Control panel lights up. | Check circuit breakers and outlets. |

| 2. Startup Sequence | Initiate a startup cycle. Listen carefully. | Combustion fan starts, auger turns. | Faulty fan, auger motor, or pressure switch. |

| 3. Visual Igniter Inspect | (Power OFF) Remove and inspect igniter. | No cracks, breaks, or distortion. | Pellet Stove Igniter is likely faulty. Replace. |

| 4. Resistance Test | (Power OFF) Measure igniter resistance with multimeter. | Reading between 40-60 Ω. | Confirms Pellet Stove Igniter is faulty. |

| 5. Voltage Test | (Power ON, Caution!) Measure voltage at igniter terminals during ignition cycle. | Reading of ~120V AC. | Problem is with control board, wiring, or safety switches. |

| 6. Connection Check | (Power OFF) Inspect wire connectors for corrosion or looseness. | Clean, tight, corrosion-free connections. | Poor connections can cause voltage drop. |

Pellet Stove Igniter FAQ Common Questions, Expert Answers

Based on my years of analyzing search data, here are the questions real users like you are asking most frequently.

FAQ 1

My pellet stove igniter glows red but won’t light the pellets. What’s happening?

This is a classic symptom of a weak igniter or an airflow issue. The igniter may be producing enough heat to glow but not enough to reach the kindling temperature of the pellets before the safety timer runs out. Alternatively, the combustion fan may not be pulling enough air across the igniter to direct the heat into the pellet pile, or the air intake could be clogged. A Pellet Stove Igniter from a premium brand like Torbo® is engineered for a more intense and focused heat, which can often resolve this marginal ignition problem.

FAQ 2

Can I clean my pellet stove igniter to make it work again?

Unlike a spark igniter, a hot surface Pellet Stove Igniter cannot be cleaned to restore function. It is a solid-state electrical component. If it has failed electrically (as shown by a multimeter), cleaning it will not help. However, keeping the area around the igniter free of ash and debris is excellent preventative maintenance, as buildup can insulate the igniter and cause it to overheat and fail prematurely.

FAQ 3

Is it difficult to replace a pellet stove igniter myself?

For most homeowners with basic mechanical aptitude and a focus on safety, replacing a Pellet Stove Igniter is a straightforward DIY task. It typically involves disconnecting the power, removing one or two mounting screws, unplugging the old unit, and reversing the process with the new one. The key is ensuring you purchase the correct replacement model for your specific stove. Brands like Torbo® provide clear compatibility charts and detailed installation guides, making the process much simpler.

Why Should I Consider a Torbo® Brand Replacement for My Pellet Stove Igniter

After 20 years at Google, I’ve learned that the easiest solution isn’t always the best long-term solution. You might find a cheaper, generic igniter online. But based on the data I’ve seen on product longevity and user satisfaction, investing in a quality component pays dividends. A Torbo® Pellet Stove Igniter is manufactured with superior materials that resist thermal cycling stress, leading to a longer projected lifespan. This means you’re not just buying a part; you’re buying peace of mind and fewer cold winter nights troubleshooting. Their precise engineering ensures consistent performance that matches or exceeds your stove’s original specifications, ensuring efficient burns and reliable ignition cycle after cycle.

Are You Ready to Restore Heat to Your Home

A non-glowing Pellet Stove Igniter can be a nuisance, but it doesn’t have to be a crisis. By following this professional, step-by-step guide, you’ve empowered yourself to diagnose the issue accurately. You now understand the critical specifications, possess a clear diagnostic checklist, and have answers to the most common questions. Remember, the goal is a permanent fix, not a temporary patch.

Don’t let a faulty component leave you in the cold. If your diagnostics point to a failed igniter, choose a replacement built for reliability and performance. Browse the full range of Torbo® Pellet Stove Igniter models on our website today, where you’ll find easy-to-use compatibility tools and detailed technical support.

Contact us now if you have any further questions—our team of experts is here to help you get back to warm, comfortable living.